Types Of Screws

Screws are one of the most common types of fasteners used in construction, manufacturing, and everyday life. They come in a wide variety of shapes, sizes, and materials, each designed for specific applications. Understanding the different types of screws and their uses can help ensure you choose the right one for your project.

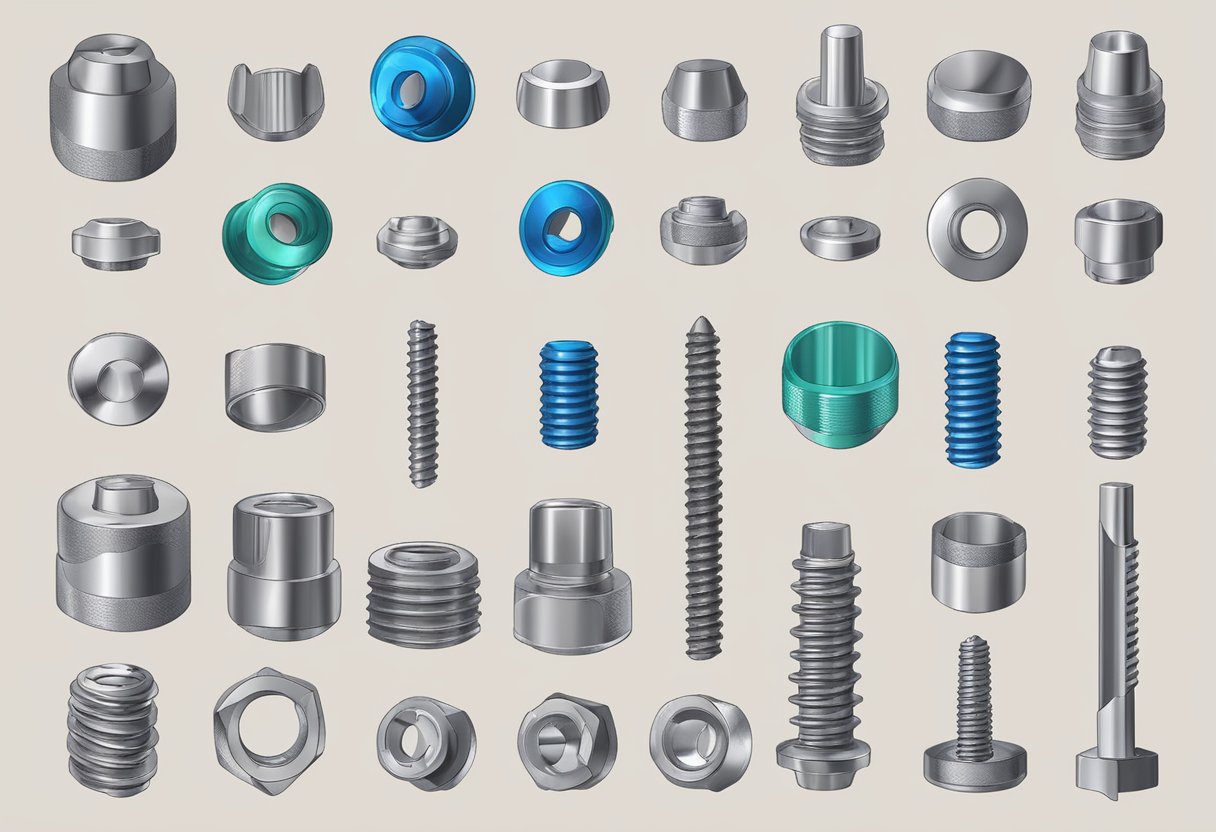

Basic screw anatomy includes the head, shank, and threads. The head is the top of the screw, where a driver tool is used to turn it. The shank is the body of the screw, and the threads are the spiraling ridges that grip the material it is driven into. Materials and coatings can also vary greatly, with options including steel, stainless steel, brass, and plastic, as well as coatings like zinc, black oxide, and chrome.

Screw types can be broken down by application, with options like wood screws, sheet metal screws, and machine screws. Specialized screws and fasteners also exist, such as concrete screws, deck screws, and drywall screws. Selecting the right screw for your project depends on a variety of factors, including the material being fastened, the load it will bear, and the environment it will be used in.

Key Takeaways

- Screws come in a wide variety of shapes, sizes, and materials, each designed for specific applications.

- Basic screw anatomy includes the head, shank, and threads, with materials and coatings that can vary greatly.

- Screw types can be broken down by application, with specialized screws and fasteners also available. Selecting the right screw for your project depends on several factors.

Basic Screw Anatomy

When it comes to understanding the different types of screws, it’s important to start with the basics. Every screw has three main components: the head, the thread, and the drive.

Head Types

Screw heads come in a variety of shapes and sizes, each with its own unique purpose. Some common head types include:

- Flat head: This type of head sits flush with the surface of the material it’s screwed into, making it ideal for applications where a smooth finish is desired.

- Round head: A round head screw is similar to a flat head screw, but with a rounded top that protrudes slightly from the surface of the material.

- Pan head: A pan head screw has a flat top with rounded sides, making it ideal for applications where a low profile is desired.

- Hex head: A hex head screw has six sides and is designed to be tightened with a wrench or pliers.

Screw Threads

The thread is the spiral ridge that runs along the length of the screw. It’s responsible for creating a tight grip between the screw and the material it’s screwed into. Some common types of screw threads include:

- Coarse thread: Coarse threads are designed for use with softer materials like wood and plastic. They have a wider pitch and are less likely to strip the material they’re screwed into.

- Fine thread: Fine threads are designed for use with harder materials like metal and concrete. They have a narrower pitch and provide a stronger grip than coarse threads.

- Self-tapping thread: Self-tapping threads are designed to cut their own thread into the material they’re screwed into, making them ideal for use in materials that don’t have pre-existing threads.

Drive Types

The drive is the part of the screw that’s used to turn it. It can come in a variety of shapes and sizes, each with its own unique advantages. Some common drive types include:

- Slotted: A slotted drive has a single slot in the head of the screw and is tightened with a flat-bladed screwdriver.

- Phillips: A Phillips drive has a cross-shaped slot in the head of the screw and is tightened with a Phillips screwdriver.

- Torx: A Torx drive has a star-shaped slot in the head of the screw and is tightened with a Torx screwdriver.

- Square: A square drive has a square-shaped slot in the head of the screw and is tightened with a square screwdriver.

Understanding the different types of screw heads, threads, and drives is essential for choosing the right screw for your project. By taking the time to learn the basics of screw anatomy, you can ensure that your projects are built to last.

Materials and Coatings

Common Screw Materials

Screws are made from various materials, each with its own set of advantages and disadvantages. The most common screw materials are steel, stainless steel, brass, and zinc. Steel screws are the most commonly used screws in construction projects. They are strong and durable, but they can rust if not coated properly. Stainless steel screws are resistant to corrosion and rust, making them ideal for outdoor applications. Brass screws are used for decorative purposes because of their gold-like appearance. Zinc screws are also commonly used in construction because they are corrosion-resistant and affordable.

Surface Treatments

Screws can be coated with various surface treatments to protect them from corrosion and rust. The most common surface treatments are galvanizing, plating, and coating. Galvanizing involves coating the screw with a layer of zinc to protect it from rust and corrosion. Plating involves coating the screw with a layer of metal to improve its appearance and protect it from rust. Coating involves covering the screw with a layer of paint or other material to protect it from corrosion and rust.

In addition to these common surface treatments, there are also specialized coatings available for screws. For example, screws used in outdoor applications may be coated with a weather-resistant material to protect them from the elements. Screws used in wood may be coated with a material that is resistant to wood rot and decay. Metal screws may be coated with a material that is resistant to chemical corrosion.

Overall, choosing the right screw material and surface treatment is important to ensure the longevity and effectiveness of the screw. It is important to consider the application and environment in which the screw will be used to determine the appropriate material and coating.

Screw Types by Application

Wood Screws

Wood screws are used for woodworking projects, both interior and exterior. They are designed to grip into wood fibers, providing a strong hold. There are different types of wood screws, such as flat head, round head, and pan head screws. The thread pattern of wood screws is also different from other screws, as it is designed to pull the screw into the wood as it is turned.

Machine Screws

Machine screws are used in metalworking projects, where a stronger hold is required. They are used to attach metal parts together, such as metal studs or sheet metal. Machine screws come in different sizes and lengths, and are typically made of metal. They are often used in construction projects, where a strong and secure hold is required.

Drywall and Masonry Screws

Drywall and masonry screws are used for attaching drywall or concrete to wood or metal studs. Drywall screws are designed to be used with drywall, while masonry screws are designed to be used with concrete or brick. Both types of screws are made of metal and come in different sizes and lengths. They are often used in construction projects, both interior and exterior.

When choosing the right type of screw for a project, it is important to consider the material being used and the type of project being undertaken. Wood screws are ideal for woodworking projects, while machine screws are better suited for metalworking projects. Drywall and masonry screws are designed specifically for attaching drywall or concrete to wood or metal studs. By selecting the right type of screw for the job, a strong and secure hold can be achieved.

Specialized Screws and Fasteners

Specialized screws and fasteners are designed to meet specific needs and requirements. They are used in various applications, including construction, automotive, and electronics. In this section, we will discuss two types of specialized screws and fasteners: self-tapping and drilling screws and structural bolts and anchors.

Self-Tapping and Drilling Screws

Self-tapping and drilling screws are designed to create their threads as they are driven into the material. These screws are commonly used in sheet metal and plastic applications. Self-tapping screws come in different types, including thread-forming, thread-cutting, and thread-rolling screws. Thread-forming screws are used in softer materials such as aluminum and plastic, while thread-cutting screws are used in harder materials such as steel. Thread-rolling screws are used in materials with a high tensile strength.

Self-drilling screws, also known as Tek screws, are designed to drill their holes and create their threads simultaneously. They are commonly used in metal-to-metal applications. Self-drilling screws come in different types, including hex washer head, modified truss head, and pan head screws. Hex washer head screws are used in roofing and siding applications, while modified truss head screws are used in HVAC applications.

Structural Bolts and Anchors

Structural bolts and anchors are used in heavy-duty applications that require high strength and durability. They are commonly used in construction and industrial applications. Structural bolts come in different types, including hex bolts, carriage bolts, and lag bolts. Hex bolts are used in structural steel applications, while carriage bolts are used in wood-to-wood applications. Lag bolts are used in wood-to-metal applications.

Anchors are used to secure objects to concrete, masonry, or other materials. They come in different types, including wedge anchors, sleeve anchors, and drop-in anchors. Wedge anchors are used in heavy-duty applications, while sleeve anchors are used in light-duty applications. Drop-in anchors are used in flush-mount applications.

In conclusion, specialized screws and fasteners are designed to meet specific needs and requirements. Self-tapping and drilling screws are used in sheet metal and plastic applications, while structural bolts and anchors are used in heavy-duty applications that require high strength and durability. It is important to choose the right type of screw or fastener for the application to ensure optimal performance and safety.

Selecting the Right Screw

When it comes to selecting the right screw, there are a few things to consider. Two of the most important considerations are size and length, as well as the type of drive head that is needed.

Size and Length Considerations

The size and length of the screw will depend on the specific application. Screws come in a variety of sizes, ranging from very small to very large. The diameter of the screw is also an important consideration. Fine threads are used for thinner materials, while coarse threads are used for thicker materials.

In addition to size, the length of the screw is also important. Longer screws are needed for thicker materials, while shorter screws are suitable for thinner materials. It is also important to ensure that the screw is long enough to provide a secure grip, but not too long that it protrudes from the material.

Determining Suitable Drive Head

The type of drive head needed will depend on the application. There are several different types of drive heads, including hex screws, slotted head, and Phillips head. Some screws also have a combination of drive heads, such as the Quadrex, which is a combination of square (Robertson) and Phillips head screws.

Coarse threads are used for materials such as wood, while fine threads are used for materials such as metal. It is also important to ensure that the pilot hole is the correct size for the screw, as this will help to prevent splitting or damage to the material.

Overall, selecting the right screw requires careful consideration of the specific application, including the size and length of the screw, as well as the type of drive head that is needed. By taking these factors into account, it is possible to choose a screw that will provide a secure and long-lasting hold for any project.