Types Of Steel

Steel is a versatile and ubiquitous material used in a wide range of applications, from construction to manufacturing to transportation. It is an alloy of iron and carbon, with other elements added to achieve desired properties. There are many different types of steel, each with its own unique composition, properties, and applications.

Classification of Steel

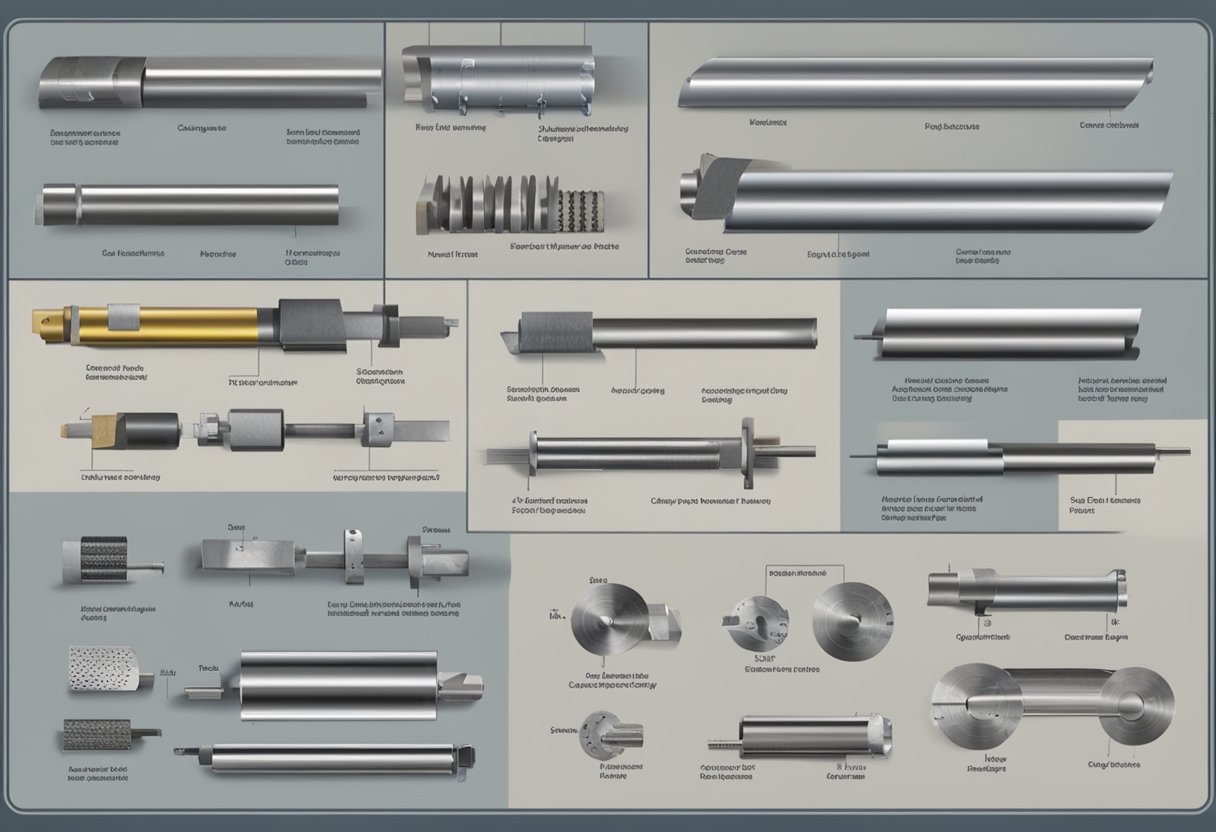

Steel can be classified into four basic types: carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is the most common type, with low to high carbon content and varying amounts of other elements. Alloy steel contains additional elements such as manganese, nickel, or chromium to improve its strength, toughness, or corrosion resistance. Stainless steel contains chromium and other alloys to resist corrosion and staining. Tool steel is used for making cutting tools, dies, and molds.

Steel Production and Composition

Steel is produced by melting iron and adding carbon and other elements to achieve desired properties. The composition of steel can vary widely depending on the type and the intended application. Steel can be produced through a variety of processes, including basic oxygen furnace, electric arc furnace, and open hearth furnace.

Properties and Applications

The properties of steel vary depending on the type and composition. Steel can be strong and durable, with high tensile strength and resistance to corrosion and wear. It can also be lightweight and flexible, making it ideal for use in construction and transportation. Steel is used in a wide range of applications, from building bridges and skyscrapers to manufacturing cars and appliances.

Key Takeaways

- Steel is an alloy of iron and carbon, with other elements added to achieve desired properties.

- There are four basic types of steel: carbon steel, alloy steel, stainless steel, and tool steel.

- Steel can be produced through a variety of processes, and its properties and applications vary widely depending on the type and composition.

Classification of Steel

Steel is a versatile material that is widely used in various industries due to its strength, durability, and ductility. Steel can be classified into four basic groups based on its chemical composition: Carbon Steel, Alloy Steel, Stainless Steel, and Tool Steel. Each group has its unique properties and applications.

Carbon Steel

Carbon steel is the most commonly used type of steel, and it is composed of iron and carbon. The carbon content in carbon steel varies from 0.06% to 1.5%. The higher the carbon content, the stronger and harder the steel. Carbon steel is classified into three grades: low, medium, and high carbon steel. Low carbon steel has a carbon content of less than 0.3%, medium carbon steel has a carbon content between 0.3% and 0.6%, and high carbon steel has a carbon content above 0.6%. Carbon steel is widely used in construction, automotive, and manufacturing industries.

Alloy Steel

Alloy steel is composed of iron and other alloying elements, such as chromium, nickel, molybdenum, and vanadium. The alloying elements are added to improve the strength, hardness, and corrosion resistance of the steel. Alloy steel is classified into two types: low alloy steel and high alloy steel. Low alloy steel has less than 8% alloying elements, while high alloy steel has more than 8% alloying elements. Alloy steel is widely used in the aerospace, automotive, and oil and gas industries.

Stainless Steel

Stainless steel is a type of steel that contains at least 10.5% chromium, which gives it its unique properties, such as corrosion resistance and high temperature resistance. Stainless steel is classified into five grades: austenitic, ferritic, martensitic, duplex, and precipitation hardening. Each grade has its unique properties and applications. Stainless steel is widely used in the food processing, medical, and chemical industries.

Tool Steel

Tool steel is a type of steel that is used to make tools, such as drills, saws, and dies. Tool steel is composed of iron and other alloying elements, such as tungsten, molybdenum, and vanadium. The alloying elements are added to improve the hardness, wear resistance, and toughness of the steel. Tool steel is classified into four types: water-hardening, air-hardening, oil-hardening, and shock-resistant tool steel. Tool steel is widely used in the manufacturing and machining industries.

In conclusion, steel is a versatile material that can be classified into four basic groups based on its chemical composition. Each group has its unique properties and applications. Understanding the different types of steel can help in selecting the right material for a specific application.

Steel Production and Composition

Raw Materials

Steel is an alloy of iron and carbon, with carbon content ranging up to 2 percent. Other elements, such as silicon and manganese, may also be added to improve the properties of the steel. The raw materials used in steel production include iron ore, coal, and limestone. Iron ore is the primary source of iron used in the production of steel. Coal is used as a fuel to heat the furnace, while limestone is used as a flux to remove impurities from the iron ore.

Smelting and Refining

The production of steel involves two main processes: smelting and refining. Smelting is the process of extracting iron from its ore using heat and reducing agents. The iron is then converted into steel by adding carbon and other elements. Refining is the process of purifying the steel to remove any impurities and improve its properties.

There are two main methods of producing steel: the basic oxygen furnace (BOF) method and the electric arc furnace (EAF) method. The BOF method involves melting iron and scrap steel in a furnace and then blowing oxygen through the molten metal to remove impurities. The EAF method involves melting scrap steel in an electric arc furnace and then adding other elements to produce the desired steel composition.

Heat Treatment

Heat treatment is a process used to improve the properties of steel by heating and cooling it to specific temperatures. This process can be used to increase the strength, hardness, and toughness of the steel. Different heat treatment methods are used depending on the desired properties of the steel.

Overall, steel production is a complex process that involves the use of various raw materials, production methods, and heat treatment processes to produce steel with specific properties.

Properties and Applications

Mechanical Properties

Steel is known for its exceptional strength and durability, making it an ideal material for a wide range of applications. The mechanical properties of steel, such as hardness and tensile strength, vary depending on the composition and processing of the steel. Hardness is a measure of a material’s resistance to indentation, while tensile strength is a measure of how much stress a material can withstand before breaking. Steel can have a hardness ranging from relatively soft to extremely hard, depending on the alloy and heat treatment used. Similarly, tensile strength can vary widely, from around 400 MPa for mild steel to over 2,000 MPa for high-strength steel.

Corrosion Resistance

One of the most important properties of steel is its resistance to corrosion. Corrosion is the gradual deterioration of a material due to chemical reactions with its environment. Steel can corrode when exposed to moisture, oxygen, and other corrosive substances. However, many types of steel, such as stainless steel, are highly resistant to corrosion due to the presence of alloying elements such as chromium and nickel. These elements form a protective oxide layer on the surface of the steel, preventing further corrosion.

Application in Industries

Steel is used extensively in a wide range of industries, including construction, infrastructure, and shipbuilding. In the construction industry, steel is used to build everything from skyscrapers to bridges to residential homes. Its high strength and durability make it an ideal material for structural applications. In the infrastructure industry, steel is used to build roads, railways, and other transportation systems. It is also used in the energy sector to build power plants and other facilities. In the shipbuilding industry, steel is used to build ships, submarines, and other marine vessels. Its high strength and corrosion resistance make it an ideal material for these applications.

Specialty Steels and Enhancements

Specialty steels are made by adding alloying elements to the base iron-carbon alloy to enhance specific properties such as strength, hardness, and corrosion resistance. These steels are used in a variety of applications including construction, automotive, and aerospace industries.

High Carbon and Low Alloy Steels

High carbon and low alloy steels are commonly used in the manufacturing of tools and machinery parts. These steels are known for their high strength, hardness, and wear resistance. The addition of alloying elements such as vanadium, tungsten, and molybdenum improves the hardenability of the steel, allowing it to be hardened and tempered to achieve the desired properties.

Vanadium, for example, is known for its ability to form extremely hard and wear-resistant carbides in steel. This makes it an ideal alloying element for high-speed tool steels. Tungsten and molybdenum, on the other hand, are known for their ability to improve the toughness and strength of steel at high temperatures. This makes them ideal for use in high-temperature applications such as jet engines and gas turbines.

Microalloyed Steels

Microalloyed steels are low carbon steels that are strengthened by the addition of small amounts of alloying elements such as vanadium, niobium, and titanium. These steels are known for their high strength and toughness, as well as their ability to be formed and welded easily.

The addition of these alloying elements promotes the formation of fine-grained microstructures in the steel, which enhances its strength and toughness. This makes microalloyed steels ideal for use in structural applications such as bridges and buildings.

In conclusion, specialty steels are an important class of materials that are used in a variety of applications. The addition of alloying elements such as vanadium, tungsten, and molybdenum can greatly enhance the properties of steel, making it stronger, harder, and more resistant to wear and corrosion. Microalloyed steels, on the other hand, are low carbon steels that are strengthened by the addition of small amounts of alloying elements, making them ideal for use in structural applications.

Environmental Impact and Cost Considerations

Steel production has a significant impact on the environment. The mining of iron ore, the primary ingredient in steel production, is a resource-intensive process that can have negative environmental consequences. The steel industry is aware of this and is taking steps to reduce its environmental impact.

One way the industry is addressing this issue is through recycling. Recycling steel reduces the need for mining and reduces the amount of waste that goes to landfills. Recycling also requires less energy than producing steel from scratch, which reduces greenhouse gas emissions and saves on energy costs.

In terms of cost, steel production can be expensive. The cost of mining, transportation, and processing all contribute to the final cost of steel. However, the cost of steel can be offset by its durability and strength. Steel is a long-lasting material that requires little maintenance, making it a cost-effective choice for many applications.

Another factor to consider when evaluating the environmental impact of steel is oxidation. Steel is susceptible to rust and corrosion, which can lead to structural damage and require costly repairs. However, advancements in technology have led to the development of more corrosion-resistant types of steel, which can reduce the environmental impact of steel production by extending the lifespan of steel products.

Overall, the steel industry is making strides to reduce its environmental impact and improve sustainability. Through recycling, the development of new technologies, and a focus on reducing greenhouse gas emissions, the industry is working to create a more sustainable future.