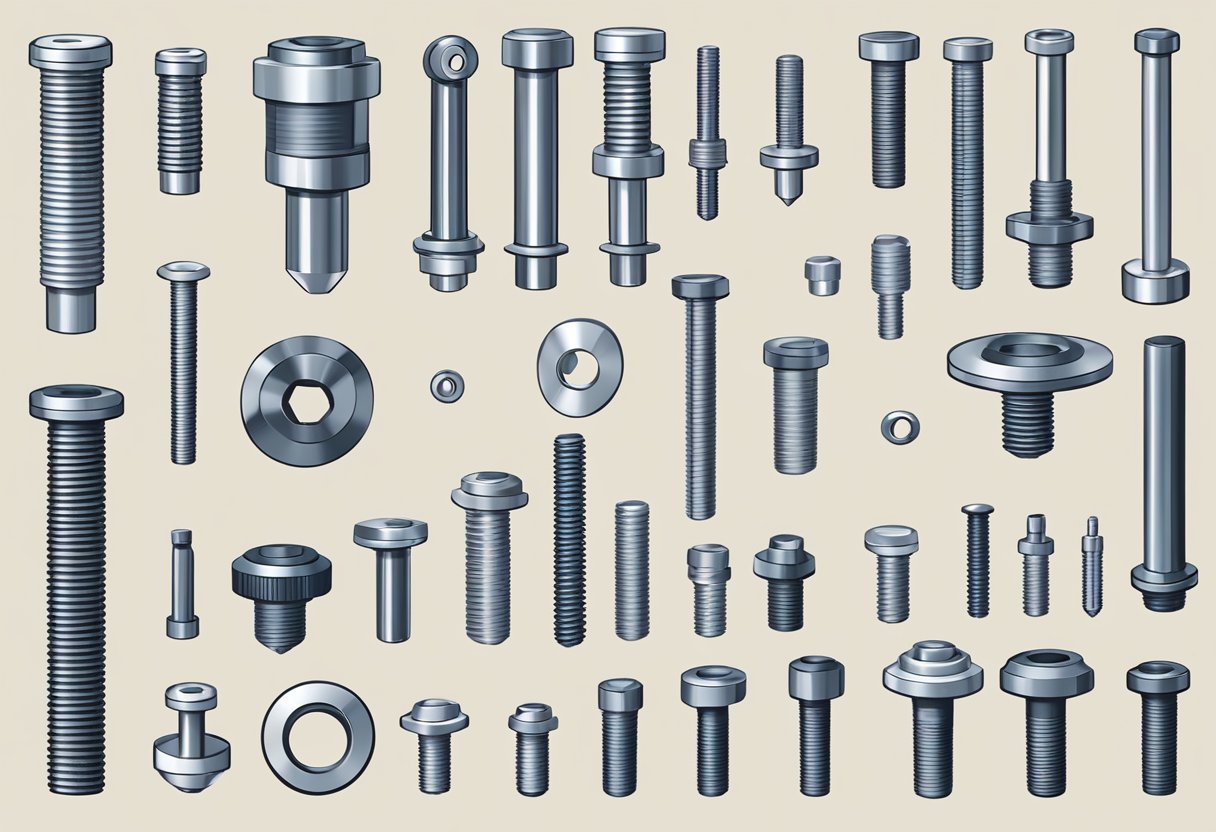

Types Of Bolts

Bolts are one of the most important components in the construction and industrial sectors. They are essential for fastening two or more materials together. Bolts come in various shapes and sizes and are made of different materials. Each type of bolt has its own unique properties and applications.

Fundamentally, bolts are threaded fasteners that are used to secure two or more objects together. They consist of a head, a shank, and a threaded portion. The head is the part of the bolt that is used to tighten or loosen it. The shank is the straight part of the bolt between the head and the threaded portion. The threaded portion is the part of the bolt that is screwed into the material to be fastened.

There are many different types of bolts available, each with its own unique properties and applications. Some of the most common types of bolts include anchor bolts, carriage bolts, eye bolts, flange bolts, hex bolts, and lag bolts. Each of these bolts has its own unique features and uses.

Key Takeaways

- Bolts are threaded fasteners used to secure two or more objects together.

- There are many different types of bolts available, each with its own unique properties and applications.

- Choosing the right type of bolt for a particular application is essential for ensuring proper performance and safety.

Fundamentals of Bolts

Materials and Composition

Bolts are mechanical fasteners that come in a variety of materials and compositions. The most common materials used for bolts are steel, stainless steel, and titanium. Steel bolts are the most widely used bolts due to their strength, durability, and cost-effectiveness. Stainless steel bolts are highly resistant to corrosion and are ideal for use in applications where exposure to moisture is a concern. Titanium bolts are strong, lightweight, and corrosion-resistant, making them ideal for use in aerospace and marine applications.

Bolt Design and Types

Bolt design and types vary depending on the application and the specifications required. Some of the most common types of bolts include hex bolts, carriage bolts, lag bolts, anchor bolts, and arbor bolts. Hex bolts are the most commonly used bolts due to their versatility and availability in a wide range of sizes and materials. Carriage bolts are designed with a rounded head and a square neck and are commonly used in wood and metal applications. Lag bolts are designed with a pointed tip and are used to fasten heavy materials to wood or other soft materials. Anchor bolts are used to secure heavy equipment or structures to concrete or masonry surfaces. Arbor bolts are used to secure cutting tools to arbors.

Threaded Fastener Mechanics

Bolts and nuts are threaded fasteners that work together to secure two or more objects together. The threads on a bolt are designed to match the threads on a nut, allowing them to be tightened or loosened by rotating the bolt or nut. The strength of a bolted joint depends on the quality and fit of the threads, as well as the material and design of the bolt and nut. The most commonly used thread standards for bolts are the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). Metric thread standards are also widely used in applications where metric units are preferred.

In summary, bolts are an essential component in many applications, from construction to automotive and aerospace. Understanding the fundamentals of bolts, including materials and composition, bolt design and types, and threaded fastener mechanics, is crucial to selecting the right bolt for the job and ensuring a secure and reliable connection.

Bolt Types and Their Uses

When it comes to fastening, bolts are an essential component. Bolts come in various types, each designed for specific applications. In this section, we will look at some of the most common bolt types and their uses.

Hex Bolts and Their Applications

Hex bolts are the most common type of bolts and are used in a wide range of applications. These bolts feature a hexagonal head and come in a variety of sizes and lengths. Hex bolts are commonly used in construction, automotive, and structural applications. They are also used in wood and metal fastening.

Machine Screws and Small Scale Fastening

Machine screws are small bolts that are used for small-scale fastening. These screws have a threaded shaft and come in a range of sizes and lengths. Machine screws are commonly used in electronic devices, appliances, and machinery. They are also used in automotive and construction applications.

Specialty Bolts for Unique Requirements

Specialty bolts are designed for unique requirements and applications. These bolts include carriage bolts, lag bolts, anchor bolts, U-bolts, eye bolts, elevator bolts, and flange bolts. Carriage bolts are used for wood-to-wood fastening, while lag bolts are used for wood-to-metal fastening. Anchor bolts are used for concrete fastening, and U-bolts are used for pipe fastening. Eye bolts are used for lifting, while elevator bolts are used for conveyor systems. Flange bolts are used for automotive and structural applications.

In conclusion, bolts come in various types and sizes, each designed for specific applications. It is essential to use the right type of bolt for the job to ensure a secure and safe fastening.

Bolt Sizes and Strength

Determining the Right Size

When it comes to selecting the right size of bolt, it’s important to consider the diameter and length of the bolt. Bolt diameter is measured in inches or millimeters, and the length is measured from the base of the head to the end of the bolt. It’s important to ensure that the bolt selected is long enough to pass through the entire thickness of the material being fastened, with enough thread remaining to secure the nut.

Grades of Strength and Material Properties

Bolt strength is typically measured in grades, which indicate the material properties of the bolt. The most common grades for bolts are Grade 2, Grade 5, and Grade 8, with each grade having its own specific bolt strength. The grade of bolt required will depend on the application and the loads that the bolt will be subjected to.

Steel is the most common material used for bolts, with carbon steel being the most popular due to its strength and affordability. Stainless steel bolts are also popular due to their corrosion resistance properties, making them ideal for outdoor applications and harsh environments. Alloy steel bolts are used in applications that require higher strength and durability.

Brass and plastic bolts are also available, but they are typically used in applications where corrosion resistance or electrical insulation is required. These materials have lower strength properties compared to steel bolts, so they are not suitable for applications where high loads are present.

In summary, selecting the right size and strength of bolt is crucial for ensuring a secure and safe fastening. Consider the application and loads that the bolt will be subjected to, and choose the appropriate material and grade to ensure a successful installation.

Bolt Installation Techniques

When it comes to bolt installation, there are several techniques that can be used to ensure that the bolts are properly fastened and secure. This section will cover the tools required for bolt fastening, as well as how to ensure proper torque and tension.

Tools Required for Bolt Fastening

Before installing bolts, it is important to have the necessary tools on hand. The tools required for bolt fastening include a torque wrench, socket wrench, pliers, and a hammer. Additionally, it is important to have the correct size and type of washers and nuts for the bolts being installed.

Ensuring Proper Torque and Tension

Proper torque and tension are essential for ensuring that bolts are fastened securely. Torque is the amount of force required to turn the bolt, while tension is the amount of force that the bolt applies to the joint. To ensure proper torque and tension, it is important to follow the manufacturer’s specifications for the specific type of bolt being used.

When fastening bolts, it is important to use the correct type of nut and washer. For example, hex nuts are commonly used with bolts, while lock nuts are used in high-vibration applications. Additionally, flat washers are used to distribute the load and prevent damage to the joint.

Fasteners can be categorized into two types: grip and friction. Grip fasteners rely on the bolt’s threads to hold the joint together, while friction fasteners rely on the friction between the bolt and the joint to hold the joint together. The type of fastener used will depend on the specific application.

In conclusion, proper bolt installation requires the use of the correct tools, nuts, washers, and fasteners, as well as following the manufacturer’s specifications for torque and tension. By following these guidelines, bolts can be installed securely and safely.

Bolt Maintenance and Corrosion Resistance

Bolt maintenance and corrosion resistance are crucial factors that determine the lifespan and effectiveness of bolts. Proper maintenance and corrosion resistance can prevent wear and tear, and ensure that bolts remain strong and effective.

Coating and Material Choices

One way to ensure corrosion resistance is by choosing the right coating and material. Zinc-coated bolts are the most common type of coated bolt and are effective in preventing corrosion. However, stainless steel bolts are even more resistant to corrosion and are ideal for use in harsh environments.

Iron bolts are also susceptible to corrosion, and bronze bolts are a good alternative for use in marine environments. Nylon bolts are another option for use in areas where conductivity is a concern.

Preventing and Addressing Wear

Preventative maintenance is key to ensuring the longevity of bolts. Regular inspection and cleaning can help prevent corrosion and wear. If corrosion is present, it is important to address it as soon as possible to prevent further damage.

One way to address corrosion is by using a rust remover or corrosion inhibitor. Applying a protective coating, such as a lubricant or paint, can also help prevent further corrosion.

In conclusion, bolt maintenance and corrosion resistance are essential for ensuring the effectiveness and longevity of bolts. Choosing the right coating and material, and implementing preventative maintenance measures, can help prevent wear and tear and ensure that bolts remain strong and effective.